Process

Process

WAX PATTERN INJECTION

Liquid wax injected into a molding die having the desired shape of final product for making wax pattern.

WAX PATTERN ASSEMBLY

The wax patterns are allied with gate, runner, pouring cup and struts according to the size and shape of the pattern.

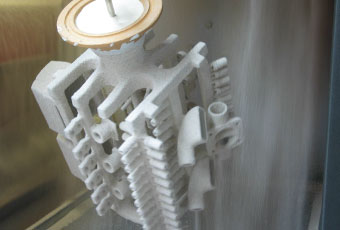

COATING

Ceramic coatings applied in the wax pattern assembly, The most important stage of the coating process is the primary coating, where a very fine grade of sand is used to get casting with excellent surface finish.

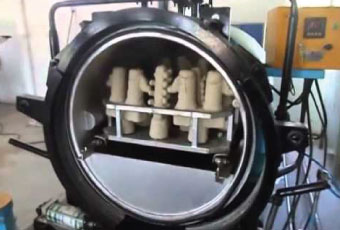

DEWAXING

Wax pattern assembly with number of coatings converted into shell after de-waxing, wax inside the solid ceramic coating being removed in liquid form with applying pressurized steam, steam pressure and cycle time are very critical parameters to be controlled during the de-waxing.

MELTING

The shells are preheated to remove moisture content and residual wax from the shell and to sinter the ceramic of shell. The specified grade melted in induction furnace is poured into pre-heated shells and shells are left for solidification.

KNOCKOUT &CUTTING

The ceramic shell is broken off by vibrating knockout machine and individual casting are cut away by arc welding or gas cut off method.

HEAT TREATMENT

Heat treatment for improving mechanical properties and to get proper microstructure results. We have batch type furnace with rapid quenching facility, Furnace is calibrated according to API 6D and there is systemized control for real time temperature of different zones.

FETTLING

We do fettling for removing of excess in gates and to finish final product with Abrasive grinding and final surface finish with greet shot blasting, Electro polishing or as per customers requirement.

FINAL INSPECTION

Inspection is the most important part of engineering processes. We do inspection of each batch with respective drawing, required instruments and gauges to insure customer requirements.

FINAL PACKING

Final products are packed in wooden box or as per requirements of customers. We apply rust preventive oil castings of carbon steel to avoid rust.